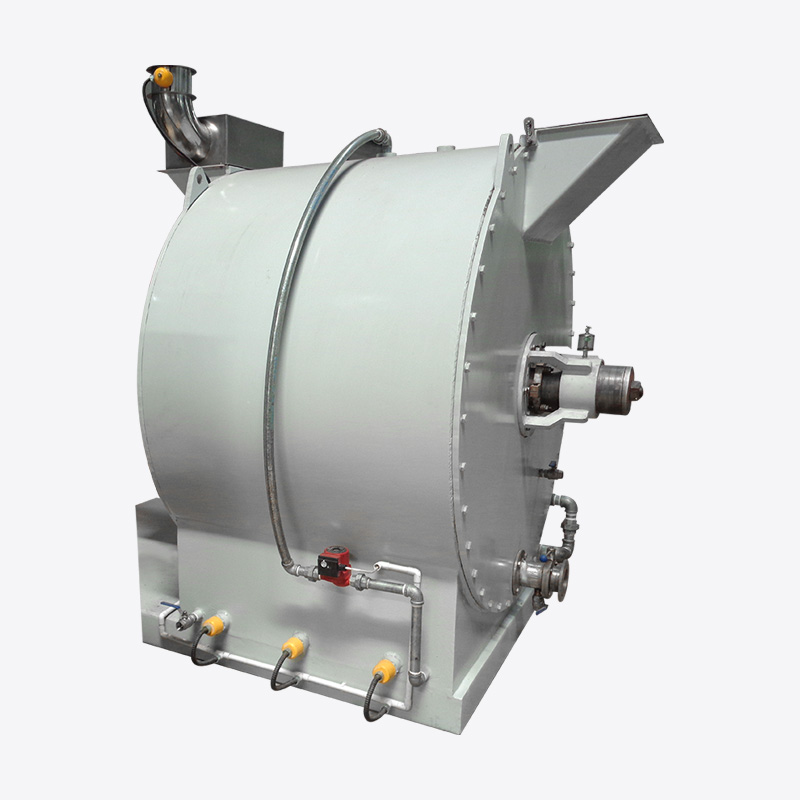

Agitators made of different materials can affect the retention rate of key flavor substances in chocolate in the chocolate conche, which is mainly attributed to the interaction between the material and the chocolate raw materials and the characteristics of the material itself. The following is a detailed analysis of this phenomenon:

1. The effect of materials on the adsorption of flavor substances

Adsorption differences:

Some materials, such as certain metal alloys, may have strong adsorption and easily adsorb flavor substances in chocolate, resulting in the loss of these flavor substances during the refining process.

However, materials such as stainless steel are relatively difficult to adsorb flavor substances, which helps to retain the natural flavor in chocolate.

Surface treatment technology:

The polishing, plating and other treatment technologies of the agitator surface will also affect its adsorption capacity for flavor substances.

For example, the surface of a stainless steel agitator that has been specially polished is smoother, reducing the contact area with flavor substances, thereby reducing the risk of adsorption.

2. The role of materials in promoting the release of flavor substances

Chemical stability:

Materials with good chemical stability, such as food-grade stainless steel, are not easy to react chemically with chocolate raw materials, which helps to maintain the original state of flavor substances in chocolate.

This means that during the refining process, flavor substances are more likely to remain in the chocolate in their original form rather than being changed or destroyed by chemical reactions.

Thermal conductivity:

The thermal conductivity of the material also affects the release of flavor substances in chocolate.

Material with good thermal conductivity can transfer heat faster, allowing the chocolate material to reach the required temperature faster during the refining process.

The appropriate temperature helps to release and evenly distribute the flavor substances, thereby improving the overall flavor of the chocolate.

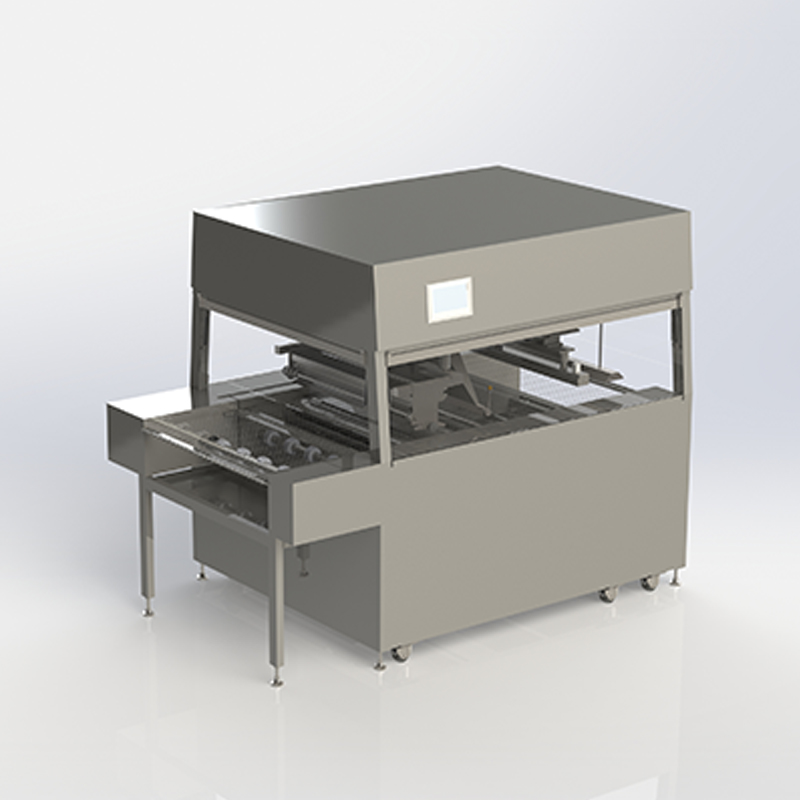

3. The impact of materials on the overall performance of the chocolate refining machine

Durability and maintenance cost:

The choice of materials also affects the overall performance and durability of the chocolate refining machine.

For example, stainless steel has good durability due to its corrosion resistance and wear resistance, which can reduce equipment failures and downtime caused by wear.

This helps to maintain the stable operation of the conch, thereby ensuring that the chocolate can fully retain its key flavor substances during the refining process.

Influence on the refining process:

The material of the agitator also affects the mixing efficiency and shear force during the refining process.

The right material and shape can ensure that the chocolate material is fully mixed and sheared during the refining process, which helps to improve the taste and quality of the chocolate.

Agitators of different materials have a significant impact on the retention rate of key flavor substances in chocolate in the chocolate conche. In order to maximize the retention of flavor substances in chocolate, it is recommended to choose materials with good chemical stability, good thermal conductivity and low absorption of flavor substances, such as food-grade stainless steel. At the same time, the shape and size of the agitator and the overall performance and operating parameters of the conching machine should also be considered to ensure that the chocolate can be best treated during the conching process.

English

English Español

Español