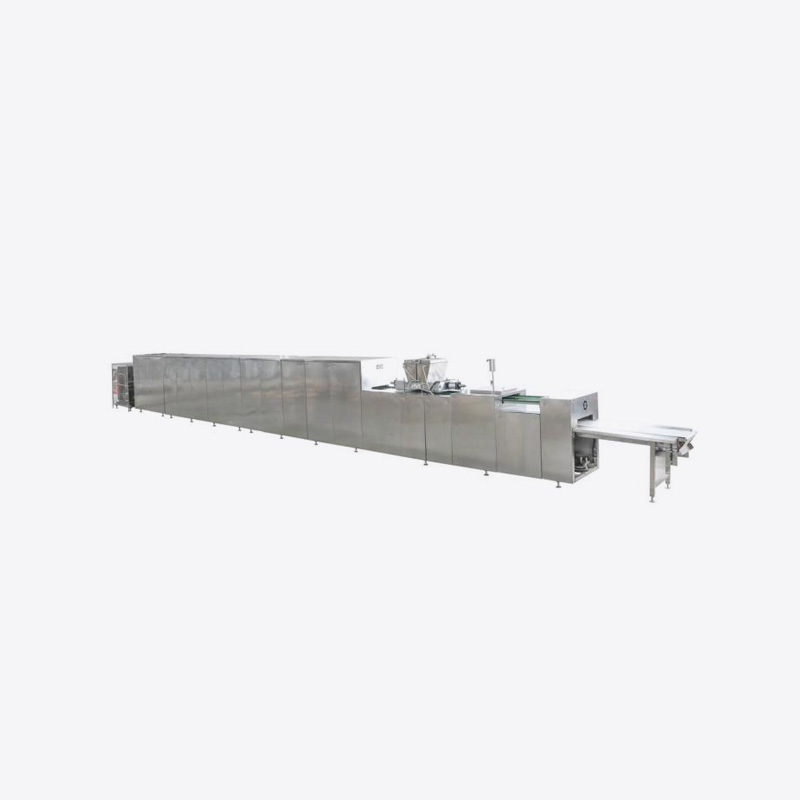

One of the key questions when evaluating a chocolate depositing line is whether the system can accommodate varying block sizes and different product specifications. This is especially important in a production environment where chocolate molds, recipes, and packaging demands can fluctuate. The answer is yes, the system can handle different block sizes, and the line is designed with flexibility and adaptability in mind. The core of this adaptability lies in the design of the cooling tunnel and conveyor system, which are crucial for ensuring efficient cooling and shaping of chocolates, regardless of size or type.

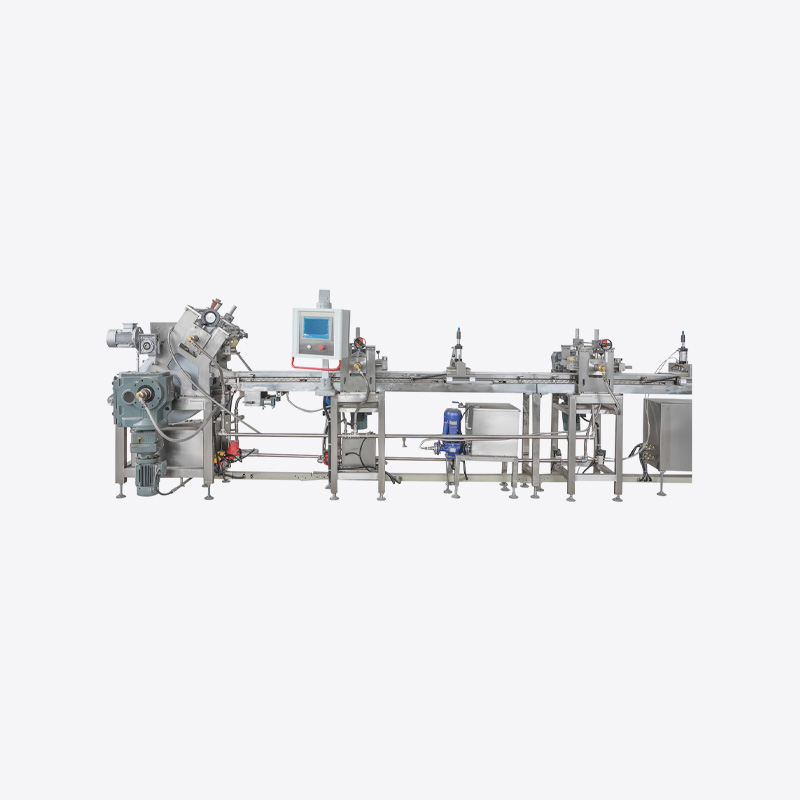

The chain conveyor system in particular is built to be robust and stable, making it capable of handling a wide range of chocolate block sizes. The flexible design allows for adjustments that cater to different molding and cooling requirements, whether you are working with small truffles or larger chocolate slabs. This means that the line can switch between various product types without requiring a complete overhaul of the system, ensuring smooth transitions and maintaining production efficiency. Whether the chocolate block is smaller, for high-volume production, or larger for premium products, the conveyor is designed to transport and cool these blocks evenly, preventing any inconsistencies in quality.

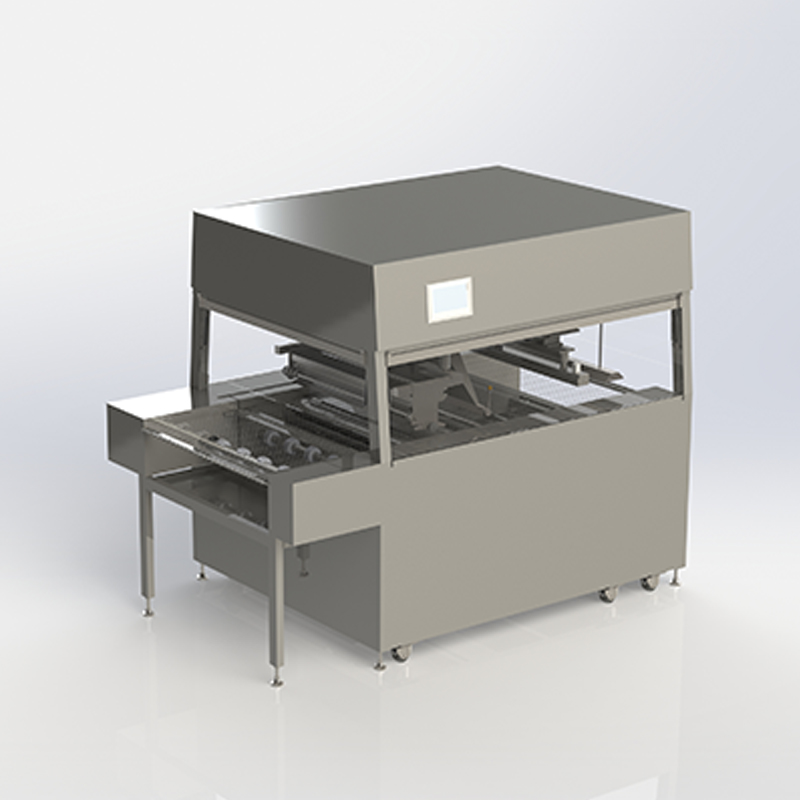

Moreover, the cooling tunnel itself is engineered for high efficiency, ensuring that even thick chocolate blocks receive the correct amount of cooling for proper molding. While thick blocks generally have more stringent cooling needs, the system can be adjusted to cater to these by fine-tuning parameters like cooling time, airflow, and temperature control. This fine-tuning capability is especially useful for chocolate producers who work with a variety of recipes, such as dark, milk, and white chocolate, each of which may have slightly different cooling requirements. Additionally, the cooling tunnel's design allows for quick setup changes to accommodate different block sizes. Instead of being locked into a single configuration, the cooling process can be tailored to suit the specific thickness and density of the chocolate being processed.

Adjustments to accommodate varying block sizes are not limited to the cooling process. The system also allows for flexibility in product specifications, whether you're making chocolates with intricate designs or simple molded blocks. The automatic chocolate molding machine that works in conjunction with the cooling tunnel can be easily adapted to different mold shapes and sizes. This adaptability is particularly useful for businesses that need to respond to changing market demands, whether it's producing seasonal items, limited-edition products, or large quantities of a standard design. By simply modifying mold sizes and adjusting the cooling parameters, the chocolate depositing line can efficiently produce a wide range of products without compromising on quality.

Beyond its ability to handle varying block sizes and product specifications, the system's overall efficiency is a significant factor in its appeal. The low power consumption, combined with high cooling efficiency, means that manufacturers can adjust the line to different product sizes without significantly increasing energy costs or reducing production speed. This makes the line an excellent investment for chocolate producers looking for a cost-effective, flexible solution that does not require constant manual intervention. The design of the conveyor and cooling system also minimizes the need for extra manpower, reducing labor costs while increasing overall productivity.

The chocolate depositing line is a versatile and efficient solution for manufacturers who need to manage different product sizes and specifications. Its ability to handle varying block sizes and make adjustments for different product types ensures that producers can maintain consistency, quality, and high throughput. Whether you’re scaling up production, launching a new product, or simply need a system that adapts to your needs, this flexible chocolate depositing line can deliver.

English

English Español

Español