-

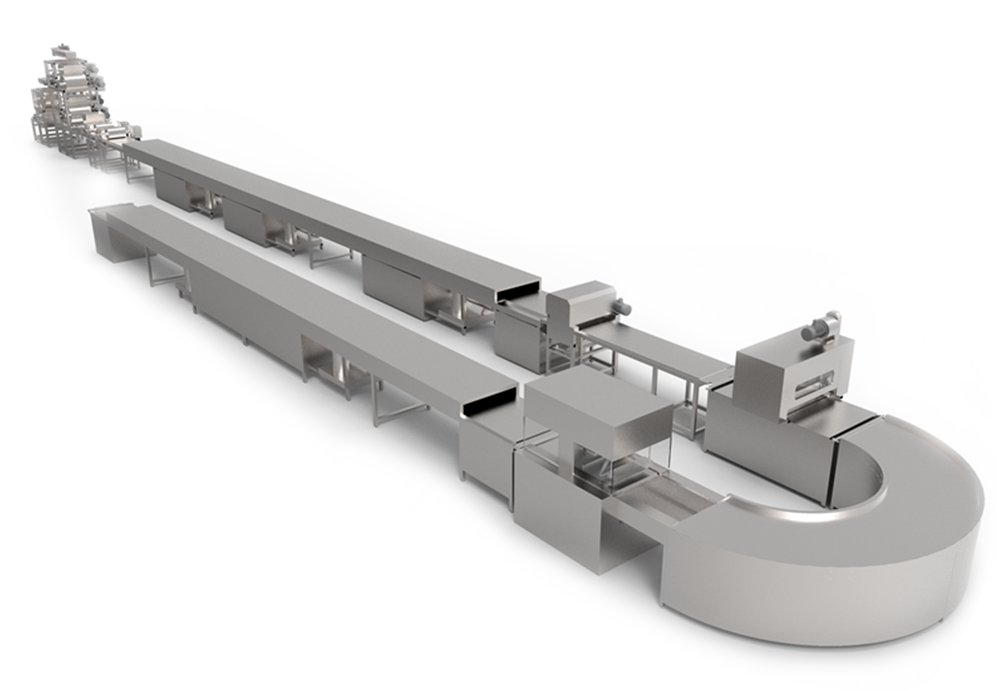

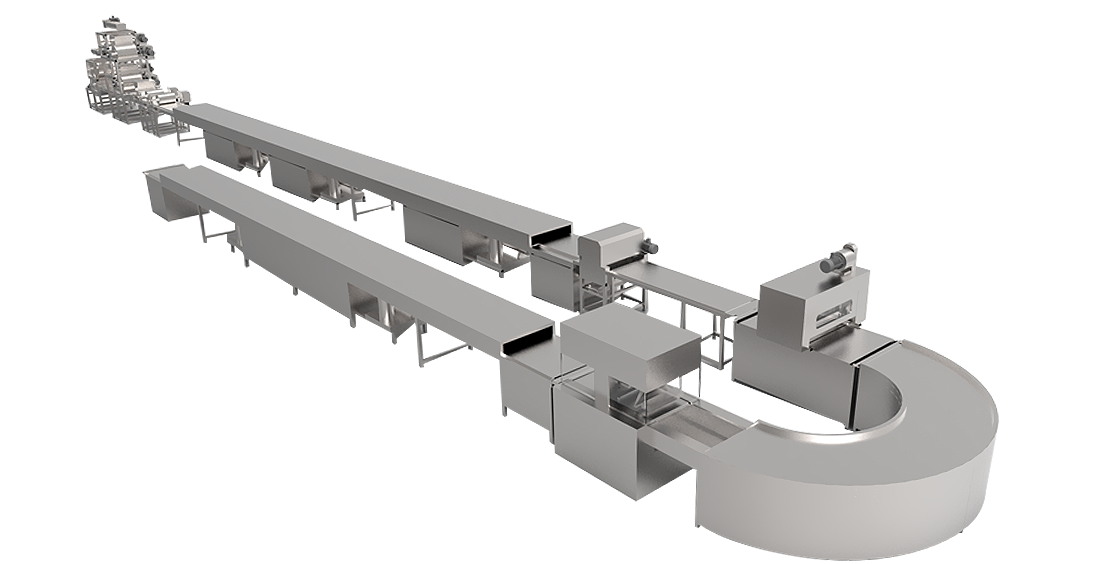

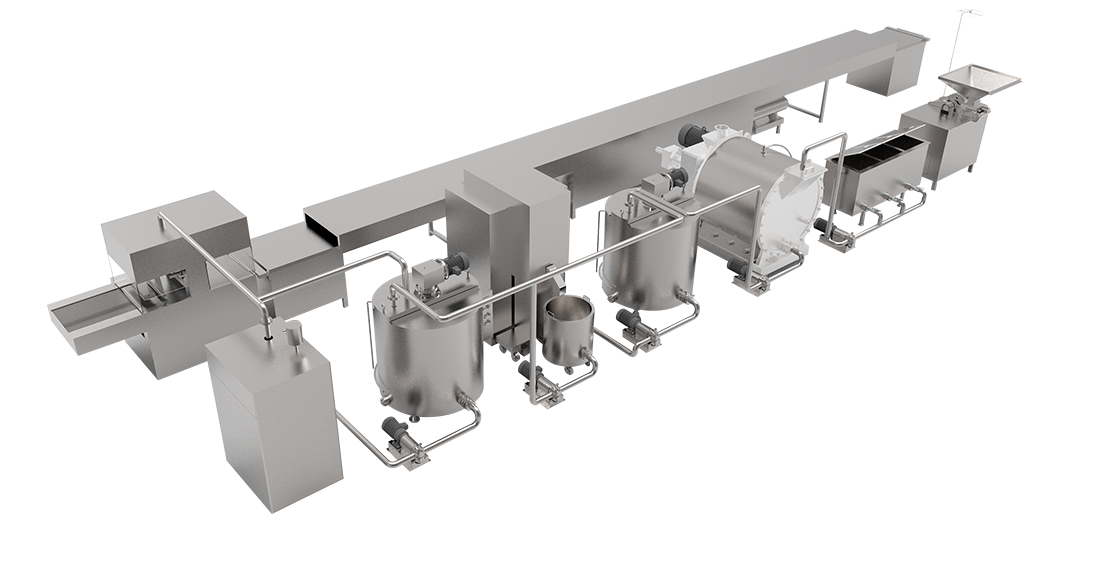

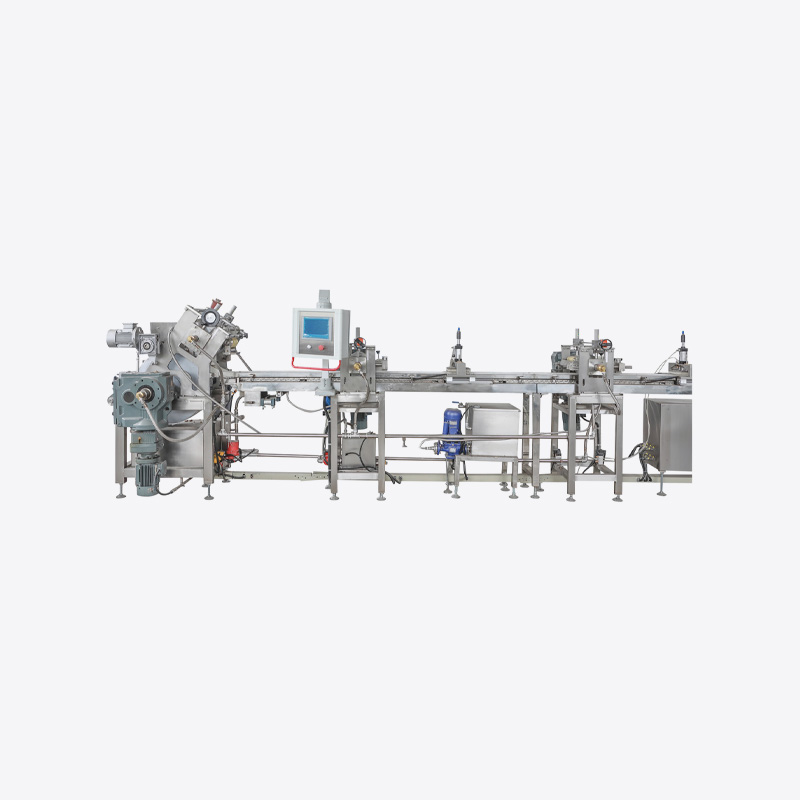

AUTOMATIC COMPOUND CANDY BAR LINE

Chocolate automatic composite candy bar production line is an efficient automatic equipment, which is specially used for the production of composite chocolate candy bars. The production line integrates raw material mixing, molding, coating, cooling and packaging. It can automatically mix different ingredients such as nuts, crushed biscuits and so on with chocolate, and then mold into candy bars. The molded candy bar is coated with chocolate to add flavor and texture, and then placed in a cooling zone for rapid curing. Finally, the finished candy bars are packaged automatically to ensure hygiene and ease of transport. The whole process has a high degree of automation and high production efficiency, which is suitable for large-scale production.

[{"left": "8%", "top": "2%", "title": "Compound Group Roller"},

{"left": "10%", "top": "10%", "title": "Particles Spreader"},

{"left": "13%", "top": "14%", "title": "Former Roller"},

{"left": "35%", "top": "30%", "title": "Cooling Tunnel"},

{"left": "54%", "top": "37%", "title": "Longitudinal Cutter"},

{"left": "45%", "top": "40%", "title": "Longitudinal Distribution"},

{"left": "76%", "top": "43%", "title": "Latitudinal Cutter"},

{"left": "54%", "top": "83%", "title": "Chocolate Enrober", "href": "https://www.gusumachinery.com/product/chocolate-production-line/chocolate-enrober/"}

]

-

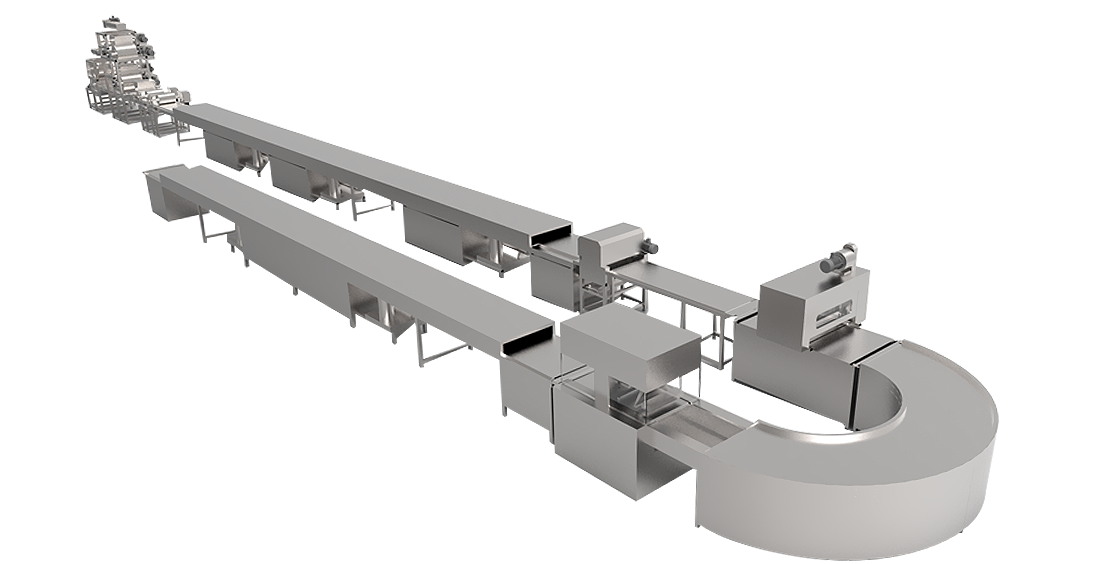

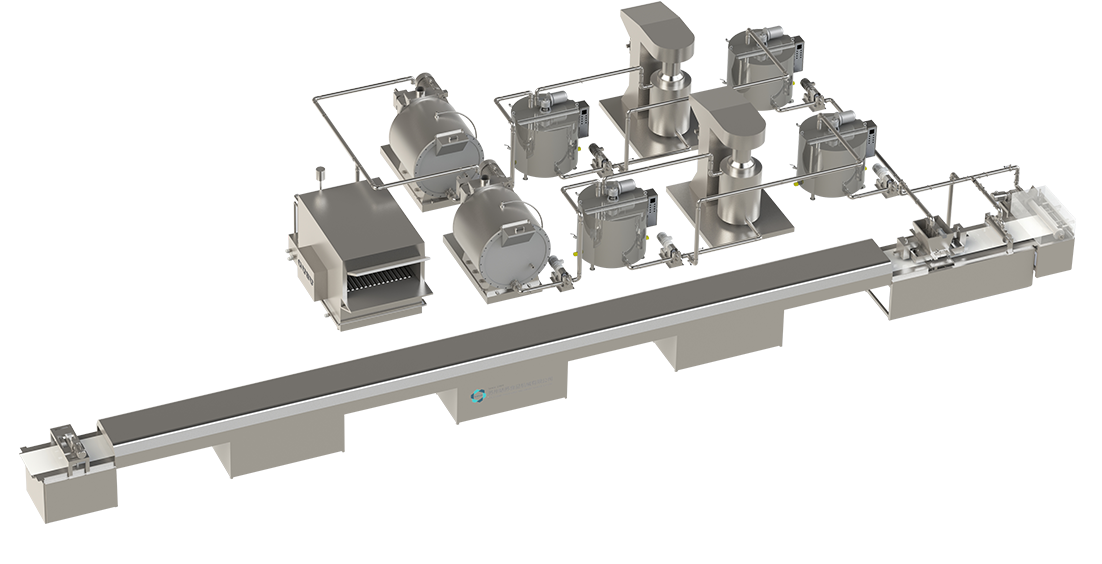

CHOCOLATE COATING PRODUCTION LINE

Chocolate coating production line is an automated equipment used to cover various foods such as candy, nuts, biscuits and so on with a layer of chocolate coating. The production line consists of several key steps: First, the food to be coated enters the production line through a conveyor belt; Next, the food is passed through the chocolate melting and insulation system, ensuring that the chocolate maintains the appropriate temperature and fluidity during the coating process; Then, the food passes through the coating machine, and the chocolate is evenly coated on the surface of the food; After coating, the food enters the cooling tunnel and quickly solidifies the chocolate coating; Finally, the coated food is collected and packaged.

[{"left": "90%", "top": "13%", "title": "Sugar Miller", "href": "https://www.gusumachinery.com/product/chocolate-machine/sugar-mill/"},

{"left": "80%", "top": "30%", "title": "Fat Melter", "href": "https://www.gusumachinery.com/product/chocolate-machine/fat-melter/"},

{"left": "75%", "top": "38%", "title": "Chocolate Pump", "href": "https://www.gusumachinery.com/product/chocolate-machine/chocolate-delivery-pump/"},

{"left": "70%", "top": "35%", "title": "Chocolate Conche ", "href": "https://www.gusumachinery.com/product/chocolate-machine/chocolate-conche/"},

{"left": "60%", "top": "42%", "title": "Storage Tank", "href": "https://www.gusumachinery.com/product/chocolate-machine/storage-tank/"},

{"left": "50%", "top": "62%", "title": "Ball Miller", "href": "https://www.gusumachinery.com/product/chocolate-machine/ball-mill/"},

{"left": "40%", "top": "67%", "title": "Storage Tank", "href": "https://www.gusumachinery.com/product/chocolate-machine/storage-tank/"},

{"left": "23%", "top": "70%", "title": "Tempering Machine", "href": "https://www.gusumachinery.com/product/chocolate-machine/chocolate-tempering-machine/"},

{"left": "15%", "top": "38%", "title": "Chocolate Enrober", "href": "https://www.gusumachinery.com/product/chocolate-production-line/chocolate-enrober/"}

]

-

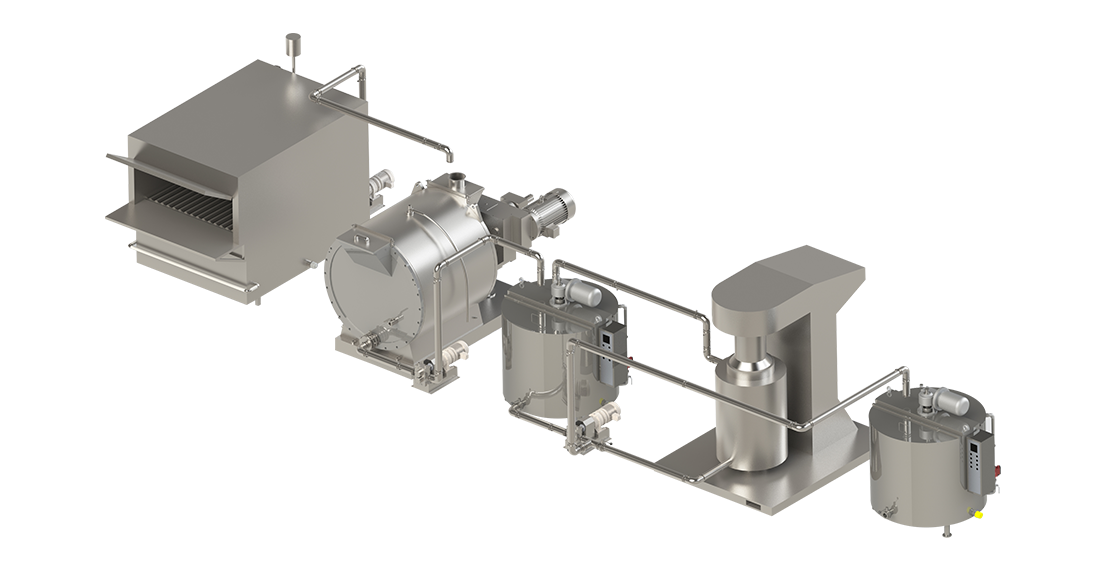

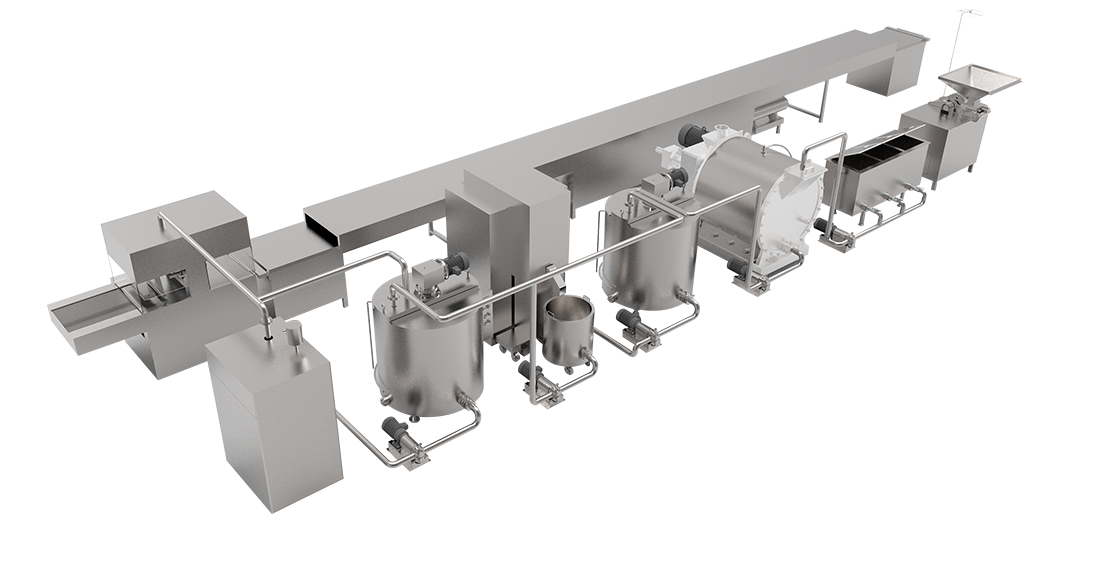

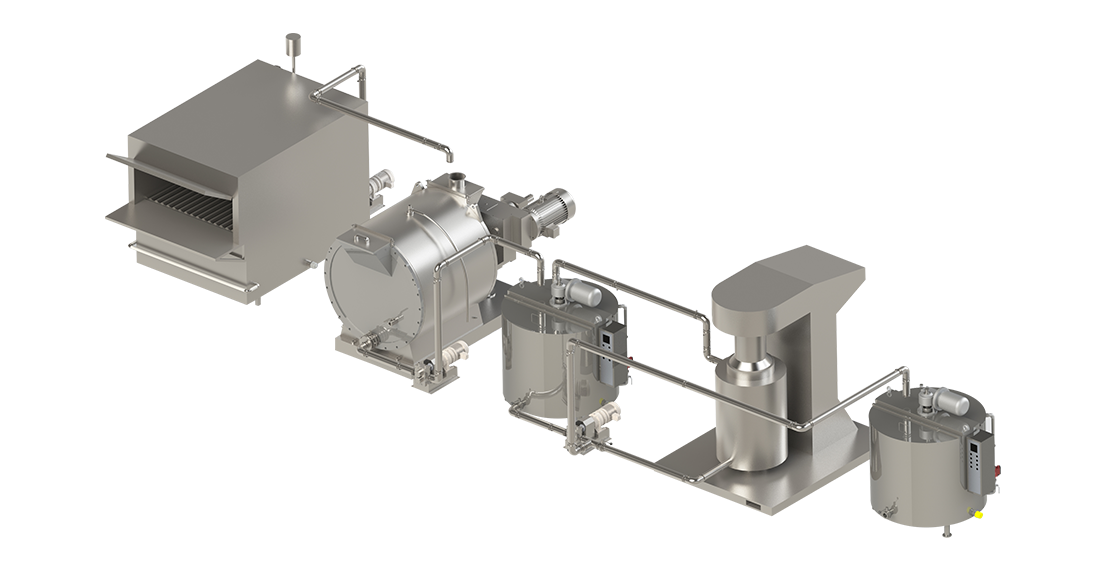

GRINDING SYSTEM

The chocolate grinding system is specially designed to grind the chocolate raw material into a fine powder. The system usually includes pre-treatment, grinding, screening and cooling. It ensures that the chocolate maintains a uniform grain size and the desired taste during grinding. The chocolate grinding system uses precision grinding machines, such as ball mills or roller mills, to achieve efficient crushing results. The screening process ensures that only chocolate powder with a specific particle size can pass through to ensure product quality. The cooling system is used to control the temperature of the chocolate, preventing the heat generated by friction during the grinding process from causing the chocolate fat to separate.

[{"left": "15%", "top": "25%", "title": "Fat Melter", "href": "https://www.gusumachinery.com/product/chocolate-machine/fat-melter/"},

{"left": "40%", "top": "35%", "title": "Chocolate Conche", "href": "https://www.gusumachinery.com/product/chocolate-machine/chocolate-conche/"},

{"left": "52%", "top": "52%", "title": "Storage Tank", "href": "https://www.gusumachinery.com/product/chocolate-machine/storage-tank/"},

{"left": "68%", "top": "60%", "title": "Chocolate Ball Mill", "href": "https://www.gusumachinery.com/product/chocolate-machine/ball-mill/"},

{"left": "80%", "top": "72%", "title": "Storage Tank", "href": "https://www.gusumachinery.com/product/chocolate-machine/storage-tank/"}]

-

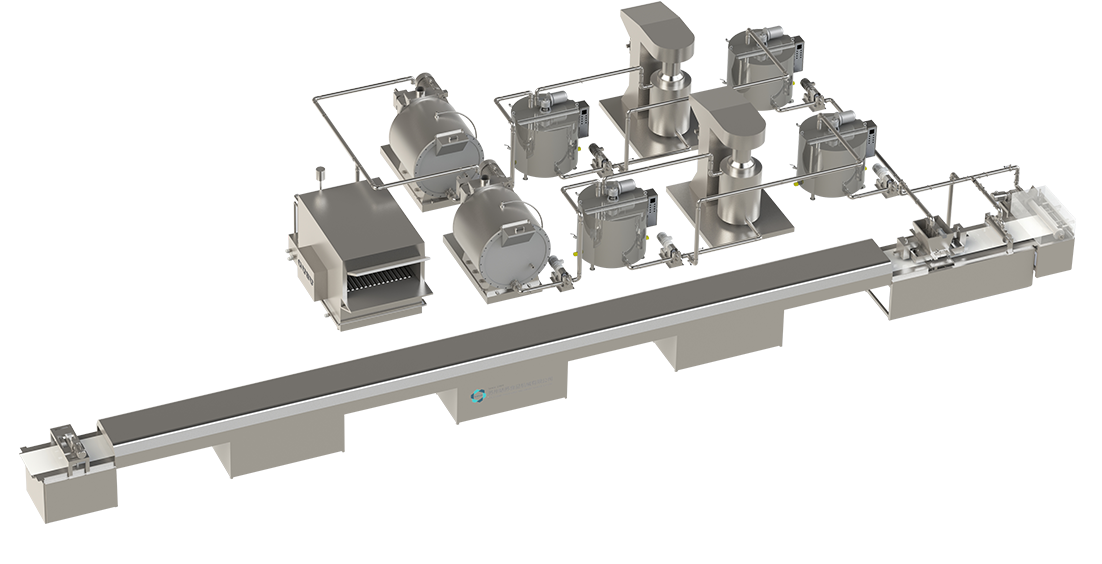

CHOCOLATE ROLLER DRIP PRODUCTION LINE

The molten chocolate is passed through a roller or dropping device to form a uniform droplet, which is then cooled and solidified. The production line usually includes a chocolate melting system, a roller drip unit, a cooling tunnel, and a packaging system. After melting, the chocolate is evenly dripped onto the conveyor belt by a precisely controlled drip device, forming uniform chocolate drops of size. These drops then enter a cooling tunnel, which is quickly cooled to fix the shape. Finally, the cooled chocolate drops are collected and packaged, ready for sale. This production line improves production efficiency, ensures the consistency of product quality, and reduces manual operation, which is suitable for large-scale production of chocolate drips.

[{"left": "28%", "top": "32%", "title": "Fat Melter", "href": "https://www.gusumachinery.com/product/chocolate-machine/fat-melter/"},

{"left": "40%", "top": "18%", "title": "Chocolate Conche", "href": "https://www.gusumachinery.com/product/chocolate-machine/chocolate-conche/"},

{"left": "45%", "top": "15%", "title": "Chocolate Storage Tank", "href": "https://www.gusumachinery.com/product/chocolate-machine/storage-tank/"},

{"left": "58%", "top": "9%", "title": "Chocolate Ball Mill", "href": "https://www.gusumachinery.com/product/chocolate-machine/ball-mill/"},

{"left": "95%", "top": "38%", "title": "Chocolate Rotary Depositor"},

{"left": "90%", "top": "45%", "title": "Chocolate Chunks Machine", "href": "https://www.gusumachinery.com/product/chocolate-production-line/chocolate-chips-rotary-depositor/"},

{"left": "85%", "top": "48%", "title": "Chocolate Chips Depositor", "href": "https://www.gusumachinery.com/product/chocolate-production-line/chocolate-chips-depositor/"},

{"left": "60%", "top": "50%", "title": "Cooling Tunnel"},

{"left": "3%", "top": "80%", "title": "Latitudinal Cutter"}]

-

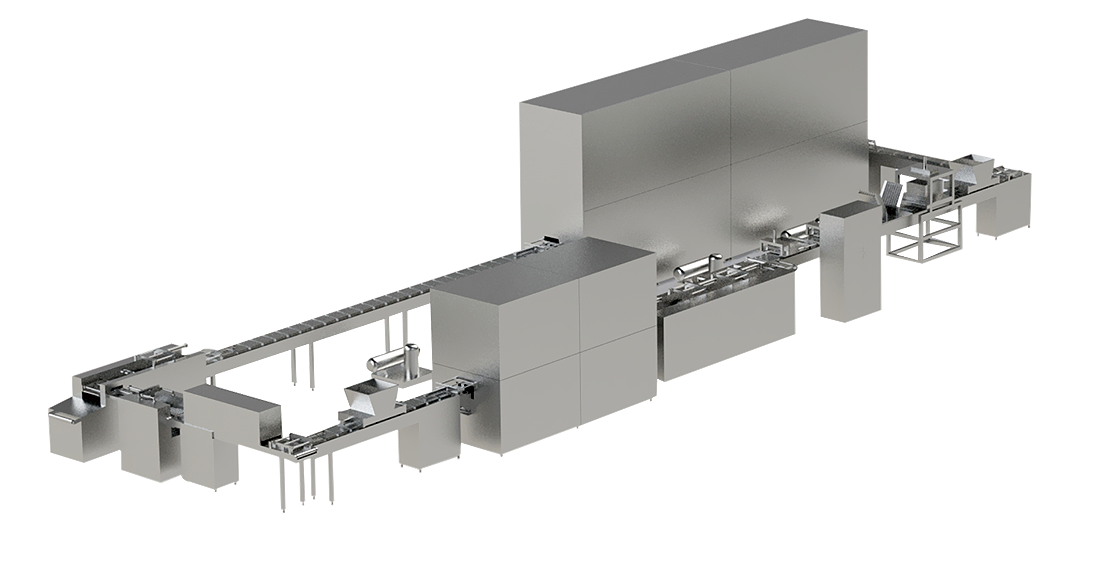

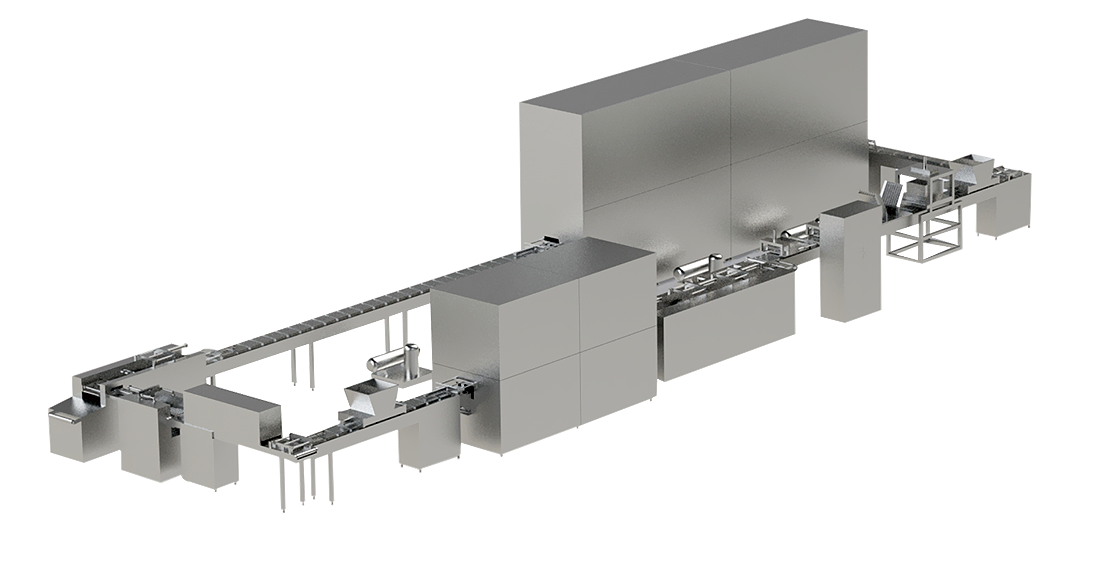

CHOCOLATE MOULDING LINE

Chocolate molding line is an automated production line specifically designed to produce chocolate of various shapes and sizes. It includes key steps such as raw material mixing, temperature regulation, pouring, cooling, demoulding and packaging. This line ensures consistent quality and shape during the molding process, while increasing production efficiency and reducing labor costs. Through precise temperature control and mold design, the chocolate molding line is able to produce beautiful and delicate chocolate products. In addition, modern chocolate molding lines are usually equipped with advanced control systems to monitor the production process, adjust parameters in time, and ensure product quality. The entire production line is designed and operated in strict accordance with food safety and hygiene standards to ensure the safety and hygiene of the final product.

[{"left": "13%", "top": "58%", "title": "Demoulding","href":"/product/"}, {"left": "50%", "top": "18%", "title": "Vertical Cooling Tunnel"}, {"left": "90%", "top": "25%", "title": "Chocolate Shell Depositing"}, {"left": "83%", "top": "37%", "title": "Filling Depositing Nuts Feeding Biscuits Feeding"}, {"left": "65%", "top": "52%", "title": "Turning Moulds Over"}, {"left": "50%", "top": "55%", "title": "Small Cooling Tunnel"}, {"left": "35%", "top": "75%", "title": "Chocolate Shell Depositing"}, {"left": "18%", "top": "80%", "title": "Mould Pre-Heating"}]

English

English Español

Español